Motor mounts, though often overlooked, are essential to ensuring a smooth, safe driving experience. They anchor the engine to the vehicle frame, absorbing vibrations, supporting engine weight, and aligning the engine for proper function. Over time, however, motor mounts can wear out, leading to potential issues that could affect performance and comfort. Knowing when to replace motor mounts is key to maintaining your vehicle’s health.

What Are Motor Mounts?

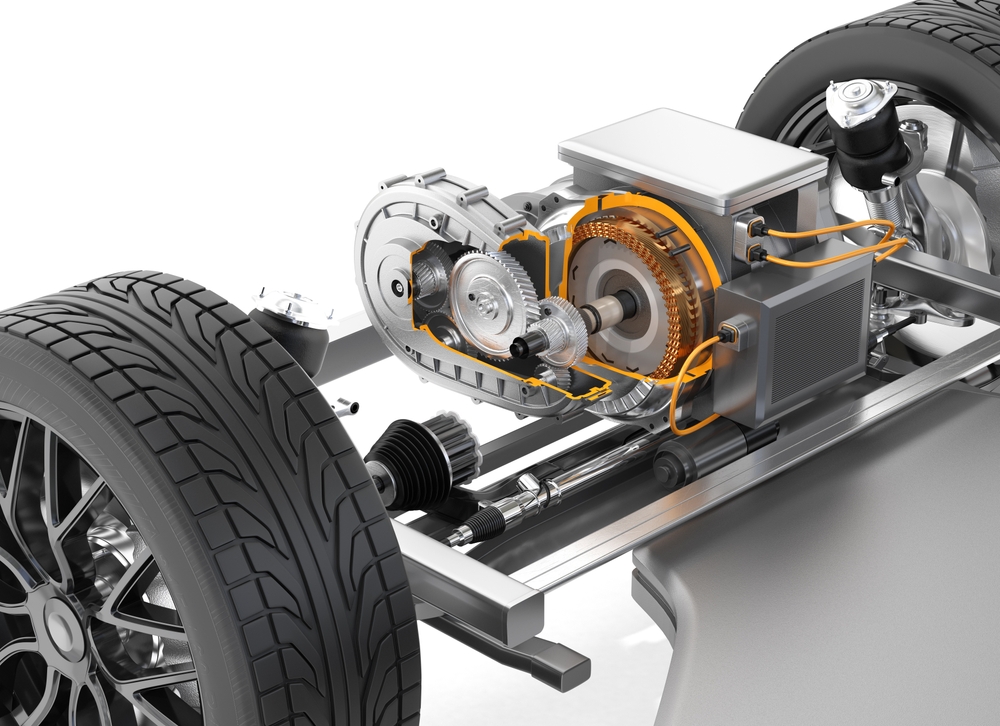

Motor mounts are components that secure the engine to the vehicle’s frame, helping to prevent excess vibration and movement. They are typically constructed with metal and rubber. The metal provides structural integrity, while the rubber absorbs vibrations, keeping the engine stabilized. This isolation protects other parts and prevents unpleasant vibrations from reaching the cabin.

When motor mounts deteriorate, their ability to absorb these vibrations and stabilize the engine diminishes, leading to a rougher driving experience.

Signs of Worn or Damaged Motor Mounts

1. Excessive Vibration

One of the most noticeable signs of worn motor mounts is excessive vibration. Under normal conditions, motor mounts dampen engine vibrations before they reach the cabin. When they wear out, vibrations intensify and become more noticeable inside the car. This issue is particularly apparent when the vehicle is idle.

2. Clunking or Banging Sounds

If you’re hearing unusual noises from the engine area, such as clunking or banging, it may indicate that the motor mounts are failing. As mounts weaken, they allow more engine movement, which can cause it to shift or tilt. This extra movement can cause metal parts to knock against each other, resulting in these alarming sounds.

3. Engine Movement or Misalignment

Open the hood while the engine is running and observe its position. If the engine appears to be moving excessively or seems misaligned, it’s a clear indicator that the mounts are not holding it firmly in place. Worn mounts can also lead to engine misalignment, which may cause more serious issues with other components, like the exhaust system.

4. Uneven Engine Position

Another indication is if the engine looks uneven or sits lower on one side. Since motor mounts provide structural support, any change in the engine’s position could be a sign of a broken or weakened mount. This misalignment can also lead to problems like exhaust leaks or worn hoses if left unaddressed.

5. Damage to Other Engine Components

Over time, deteriorated motor mounts can lead to issues with nearby components. A misaligned engine, for example, can place strain on exhaust connections, potentially causing leaks. Damaged mounts might also compromise the integrity of the transmission mounts or axles.

If you’re noticing these symptoms, consulting a professional to evaluate the motor mounts may be wise.

Causes of Motor Mount Failure

Understanding why motor mounts fail can help you take steps to extend their life. Here are the main factors:

- Wear and Tear: Like any part, motor mounts degrade with time. The constant exposure to engine heat and pressure, combined with the vehicle’s vibration, wears down the rubber component.

- Aggressive Driving: Hard accelerations, frequent gear changes, and sudden stops put extra stress on motor mounts, increasing wear.

- Fluid Leaks: Leaks from the engine, transmission, or other parts can degrade the rubber in motor mounts, accelerating their failure.

- Engine Misfires or Rough Idle: These issues can cause the engine to move irregularly, putting undue stress on the mounts.

To prevent motor mount failure, regular inspection and maintenance are essential.

Consequences of Driving with Faulty Motor Mounts

Ignoring motor mount issues can lead to serious problems. Here’s what to expect if worn motor mounts are left unaddressed:

- Engine Damage: A misaligned engine can experience additional wear on components like the exhaust system and transmission.

- Transmission Issues: Since motor mounts help align the engine and transmission, worn mounts may cause transmission misalignment, affecting performance and causing issues when shifting gears.

- Increased Vibration and Noise: Excessive vibration from faulty mounts may create an uncomfortable ride and could even damage interior components due to the persistent shaking.

If motor mounts are causing excessive vibration, scheduling an inspection can help identify the best course of action.

How to Inspect Motor Mounts

If you’re comfortable examining motor mounts, there are some telltale signs you can look for:

- Visual Inspection: Look for visible cracks or tears in the rubber section of the mounts. Check if the engine appears aligned and sits securely.

- Prying Test: With the car safely elevated, use a pry bar to gently test the motor mount’s movement. Excessive movement is a sign that the mounts may need replacement.

- Engine Observation: Observe the engine while someone else starts and revs it. If it tilts excessively, this could signal mount wear.

For detailed guidance, check out this video tutorial on motor mount inspection.

Motor Mount Replacement: DIY or Professional Service?

While replacing motor mounts can be done by those with advanced car repair skills, it’s often best left to professionals due to the complexity of the job. Here are some reasons to consider professional service:

- Safety Concerns: Handling a vehicle’s engine requires caution and experience, especially with the weight and precision involved.

- Proper Tools: Replacing motor mounts requires specific tools and equipment, such as a hydraulic jack and engine hoist.

- Quality Assurance: A professional will ensure that the new mounts are properly aligned, reducing the risk of premature wear.

If you decide to replace them yourself, be sure to follow all recommended safety protocols and use trusted parts and materials.

Types of Motor Mounts

Depending on your vehicle, there are different types of motor mounts that might suit your needs:

- Rubber Mounts: The most common type, rubber mounts are effective at absorbing vibrations and affordable but may wear faster.

- Hydraulic Mounts: These mounts use fluid-filled chambers to absorb vibrations. They are more effective but can be costly.

- Polyurethane Mounts: These mounts provide high performance and durability but may increase vibration.

- Solid/Performance Mounts: Often used in performance vehicles, solid mounts offer the best support for high-speed driving but transmit more vibration to the cabin.

Selecting the right motor mount can impact your vehicle’s performance and comfort. For expert advice, consult a professional mechanic who can help you choose the best option for your vehicle.

How Often Should Motor Mounts Be Replaced?

Motor mounts don’t have a strict replacement schedule but generally last around 5 to 7 years, depending on driving conditions. Some factors affecting their lifespan include:

- Driving Style: Frequent hard accelerations can cause mounts to degrade faster.

- Mileage: Higher mileage vehicles tend to experience more mount wear.

- Environmental Conditions: Constant exposure to extreme temperatures can shorten a mount’s lifespan.

For vehicles used for high-performance driving, mounts may need more frequent checks. If you’re planning a long road trip, it’s wise to include a motor mount inspection in your vehicle maintenance checklist.

Cost of Motor Mount Replacement

The cost of motor mount replacement varies based on vehicle make, model, and the type of motor mounts used. In general, replacement costs include:

- Parts: Depending on the mount type, parts can range from $50 to $200 each.

- Labor: Replacing motor mounts is labor-intensive, with labor costs ranging from $150 to $450 or more.

To get a clear estimate, consult with a trusted repair shop. Factors like engine type, accessibility, and the number of mounts can affect overall costs. Additionally, choosing high-quality motor mounts can provide better durability and performance.

Preventing Motor Mount Wear

While motor mount wear is inevitable over time, taking preventive steps can extend their lifespan:

- Drive Smoothly: Avoid rapid acceleration and sudden stops to reduce stress on the mounts.

- Inspect Regularly: Incorporate motor mount checks into your regular car maintenance routine.

- Check for Leaks: Address fluid leaks immediately to prevent rubber degradation in the mounts.

- Schedule Professional Inspections: Regular visits to a professional mechanic ensure that potential issues with motor mounts and other essential components are caught early.

Following these simple maintenance tips can go a long way in preserving the lifespan of your motor mounts.

Frequently Asked Questions About Motor Mount Replacement

To fully understand when and why to replace motor mounts, there are several questions that often come up. From costs and compatibility to signs of potential damage, let’s dive into some additional details to address the most common concerns.

How Do Motor Mounts Affect Vehicle Performance?

Motor mounts directly impact engine stability and vehicle performance. When in good condition, they hold the engine firmly in place and prevent excess vibrations. This not only ensures a smoother ride but also keeps other engine components correctly aligned. Faulty mounts, however, can lead to performance issues:

- Inconsistent Engine Power: Loose or damaged mounts allow the engine to shift more freely, which can affect how power is transferred to the transmission and wheels, especially during acceleration.

- Fuel Efficiency: With the engine misaligned, fuel usage may increase as it needs to work harder to maintain stability.

Maintaining motor mounts in good condition helps improve engine performance, reduce fuel consumption, and ensure smooth transmission operation.

Can Bad Motor Mounts Cause Transmission Problems?

Yes, worn motor mounts can lead to transmission issues. Since motor mounts help maintain engine alignment, any movement can affect the drivetrain. This misalignment can place strain on the transmission mounts and shift the position of the drivetrain components, leading to potential damage. Symptoms of transmission issues caused by bad motor mounts include:

- Hard Shifting: Misaligned engines may result in hard or erratic shifting.

- Gear Slippage: Excessive movement may interfere with proper gear alignment.

For vehicles with manual transmissions, motor mounts in poor condition may also cause the clutch to engage or disengage improperly, which can lead to clutch wear or even failure over time.

How Long Do Motor Mounts Typically Last?

Motor mounts generally last between 60,000 and 100,000 miles, although this can vary based on driving style, conditions, and maintenance practices. While high-performance or off-road vehicles may experience shorter motor mount lifespans due to greater stress, sedans and daily drivers can often go longer between replacements. Here are some factors that affect motor mount lifespan:

- Frequent Hard Accelerations: Heavy acceleration can strain the mounts.

- Environmental Exposure: Extreme temperatures or road salt can lead to faster degradation.

- Age of the Vehicle: As vehicles age, motor mounts naturally weaken and may need replacement.

Regular inspections, especially around the 60,000-mile mark, can help detect early signs of wear and allow for timely replacement.

Are Aftermarket Motor Mounts a Good Option?

When it comes to motor mounts, vehicle owners can choose between original equipment manufacturer (OEM) and aftermarket options. Here’s a breakdown of each:

- OEM Motor Mounts: These are designed specifically for your vehicle’s make and model, ensuring compatibility and performance similar to the original parts. While often more expensive, they provide a high level of reliability.

- Aftermarket Motor Mounts: These may vary in quality and performance but are generally less expensive than OEM parts. Some aftermarket options, like polyurethane mounts, are durable and offer high performance, making them suitable for those looking for enhanced durability in performance vehicles.

Choosing between OEM and aftermarket motor mounts depends on your priorities—whether it’s maintaining the original ride quality or seeking more cost-effective options. Consult with a professional to make the best choice for your vehicle’s specific needs.

How Do You Test Motor Mounts for Wear?

If you suspect motor mounts are worn, there are a few simple ways to test them at home. While a professional evaluation is ideal, especially if you’re unsure, these methods can provide insight into the condition of your motor mounts:

- Visual Inspection: Look for obvious cracks or deformation in the rubber part of the mount. If the rubber appears split, torn, or overly worn, it’s a sign the mount needs attention.

- The “Power Brake” Test: With the vehicle in drive and one foot on the brake, gently press the gas pedal while holding the brake. If the engine shifts significantly, this movement can indicate worn mounts.

- Rev Test: Observe the engine while a second person revs it. Excessive tilting or shaking suggests weak motor mounts.

These tests provide initial indicators, but for confirmation, it’s best to schedule an inspection with a certified mechanic.

What Happens if You Don’t Replace Motor Mounts?

Ignoring worn motor mounts can result in further complications, some of which may become costly to repair. Over time, failing mounts can lead to the following:

- Damage to Transmission: Misaligned engines cause wear on the transmission, potentially leading to fluid leaks, hard shifting, or damage to transmission gears.

- Increased Wear on Exhaust Components: An engine that moves excessively can put stress on the exhaust system, leading to leaks or broken exhaust connections.

- Cabin Noise and Vibration: Persistent noise and vibration from deteriorating mounts can eventually impact the vehicle’s resale value, as well as make driving uncomfortable.

Replacing motor mounts as soon as symptoms appear helps prevent these complications and maintains a smooth, safe ride.

Can You Replace Motor Mounts Yourself?

Replacing motor mounts requires specific tools and a secure working environment. Although it’s possible for skilled DIYers, there are some challenges:

- Engine Support: Lifting the engine slightly to remove old mounts and install new ones requires a hydraulic jack or engine hoist, which may be outside the range of standard DIY equipment.

- Alignment Precision: Ensuring the engine is perfectly aligned after replacement can be tricky. Incorrect alignment may lead to future wear on mounts and other components.

Due to these factors, motor mount replacement is often best handled by a professional technician to avoid potential issues. If you’re considering the DIY route, ensure you have access to the right tools and information before beginning the process.

Are There Different Types of Motor Mounts for Performance Vehicles?

Performance vehicles often benefit from specialized motor mounts that support high engine torque and speed. Here’s a quick look at some options:

- Polyurethane Mounts: Known for their durability, these mounts withstand higher torque and heat levels, making them popular for performance applications.

- Solid Mounts: Solid metal mounts offer maximum stability for high-speed driving and aggressive acceleration. However, they may increase vibration in the cabin.

- Active or Hydraulic Mounts: These are high-tech mounts that adjust vibration absorption based on driving conditions. While expensive, they provide excellent balance between performance and comfort.

For high-performance vehicles or aggressive driving styles, selecting the right type of mount enhances handling and control, though it may come at the cost of some cabin comfort. Consult a performance specialist if you’re interested in exploring high-performance motor mounts.

How Long Does Motor Mount Replacement Take?

Motor mount replacement time can vary depending on vehicle make, model, and the mount’s location. Typically, the process takes between 1.5 and 4 hours. Here’s what factors into this time frame:

- Accessibility: Some motor mounts are located in hard-to-reach spots, requiring parts like the transmission or exhaust components to be moved.

- Tools Required: Mounts often require special tools for proper alignment and secure installation, which can add to the time if done manually.

If you’re curious about the specific time estimate for your vehicle, consulting with a mechanic can provide a clearer picture of what to expect.

Why Prompt Motor Mount Replacement Matters

For vehicle owners, motor mounts are one of those components that might seem minor but play a big role in vehicle health. Prompt replacement can prevent expensive repairs down the road and keep your driving experience comfortable. Regular checks as part of routine vehicle maintenance ensure that issues are caught early, avoiding more extensive (and costly) repairs.